Definition / Closed Oven Rock And Roll Rotomoulding Machine

Close Oven rock and roll rotomoulding machine is also part of rotomoulding technology which is used to manufacture each kind of hollow articles product. we thought through the idea of manufacturing this kind of machine which selected as an economical choice as per current market circumstances. Because closed oven rock and roll rotomoulding machine is economical in terms of investment and production cost.

Rotational moulding process products has long life span. Rotomoulding machines have various categories knows as four/three arm bi axial rotomoulding machine, open fire rock and roll rotomoulding machine and closed oven rock and roll rotomoulding machine. These machines have same production process, but some factors are different in most terms as mentioned, production cost, power consumption, production rate, cost of operation, cost of maintenance.

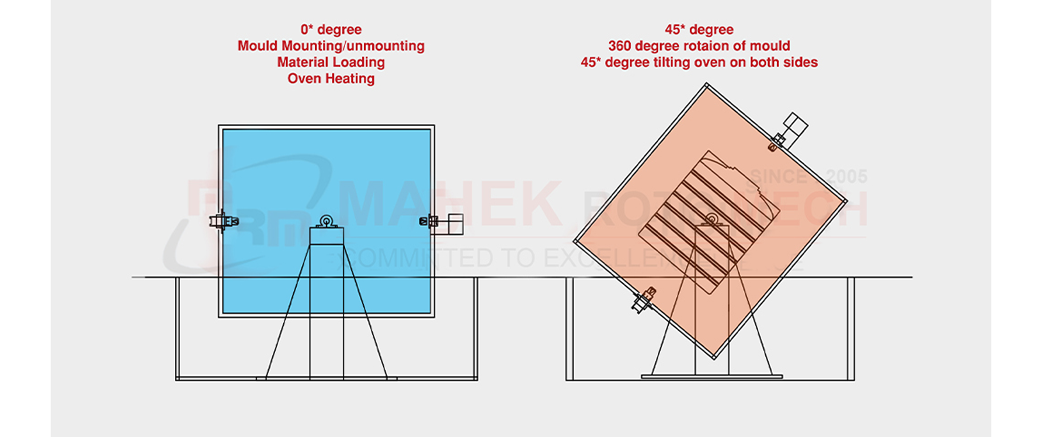

How It Works :

In the process, A plastic material (lldpe powder) is in powder state is inserted into a mould, which are fabricated from mild steel or stainless steel. The mould is then closed and fitted inside the oven box. The mould starts to get heated in an oven whilst rotating 360 degree horizontally and oven box tilts at 45 degree on the both sides for several time during the process cycle until the powder gradually melts and ‘lays-up’ on the inside of the mould. Once the powder has completely melted the mould is moved out and migrated to a cooling spot and gets cooled with air with the help of cooling fans. the plastic powder comes into solid state. When the material gets completely cooled, the next step is to release that away from the mould surface. finally arm moves to the unloading spot and the product is taken out of the mould and then again cycle repeats.

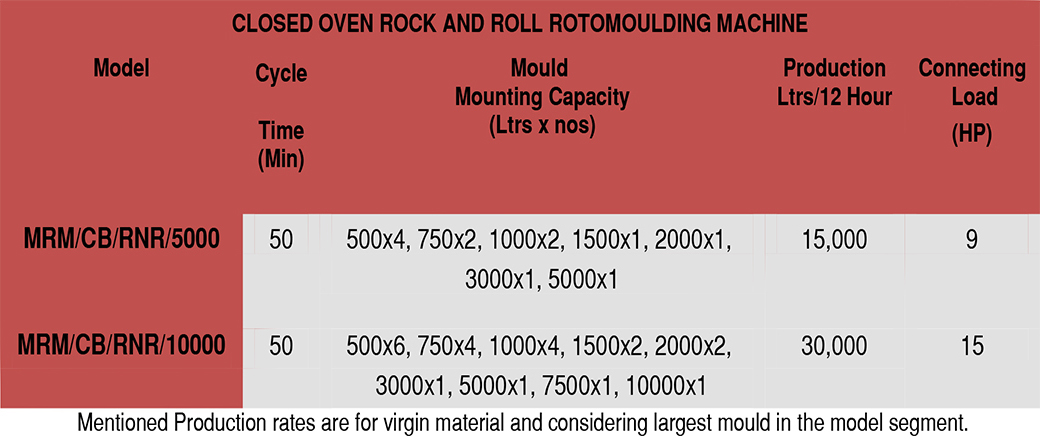

Range Of Models & Production Capacity :

Closed oven rock and roll rotomoulding machine (100 to 5000 Ltrs) : MRM/CRNR/ROTO/5000

Closed oven rock and roll rotomoulding machine (100 to 10,000 Ltrs) : MRM/CRNR/ROTO/10000

+ More models available as per requirement

Maximum Production Capacity Upto 25,000 ltrs in a single time.

Important Features:

- Low Investment (best for start up)

- Less installation space required

- Low fuel consumption

- Low power consumption

- Low maintenance

- Less man power required (1 skilled operator required

- Hydraulic cylinder for Door open/close and oven box tilting

- Easy operation

- Eligibility to produce up to six layer tanks due perfect distribution of material

- Oven heated with help of LPG by shifting nozzle and gas firing system.

Optional attachments :

- Powder loader machine (Blower provided to fill powder into the mould with less efforts)

- HMI based control panel (advanced operating technology with touch screen and automation facility)

- pneumatic spanner with air compressor (to open/close moulds rapidly + saves time)