.jpg)

Plastic Granules Making Machine / Plastic Dana Making Machine

We are one of the largest firm, are a leading Manufacturer of Plastic Dana Making Machine, Scrap Grinder Machine, Extruder Machine, and many more. Plastics Recycling Machine works on a principal of plastic extrusion process. is a normally high volume production process where a plastic polymer material, enriched with the desired additives, melted and formed in a continuous process. Where output can get in form of granules.

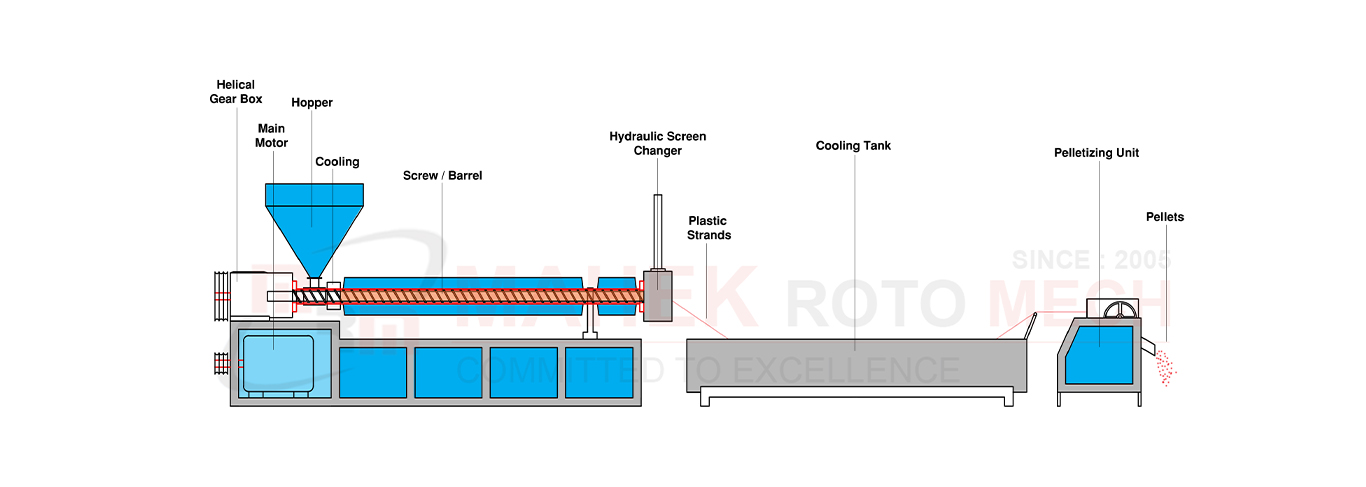

How It Works :

In the process, A plastic material would be in plastic flakes form is inserted into extruder’s hopper, usually fabricated from mild steel or stainless steel as per material requirement. Hopper magnet fitted inside the hopper to resist metallic particles from entering inside the barrel. Raw material in the state of plastic flakes, is gravity fed into the hopper and reaches the rotating screw. Barrel has several nos of heaters fitted on the outer diameter. Which heats up the barrel to help the extrusion process to be done. Screw is fitted with helical gearbox and AC motor which rotates the screw. Raw material in flakes form initials to move further along the rotating screw and enters the heating spot of barrel, Where it starts to melt. Molten plastic reaches the end side of the barrel where hydraulic screen changer is fitted which filters the molten plastic and converts it into plastic threads. Plastic threads moves forward and goes through the stainless steel water tank and temperature starts to drop. Plastic threads then enters the pelletizer machine which turn it into pellets.

.jpg)

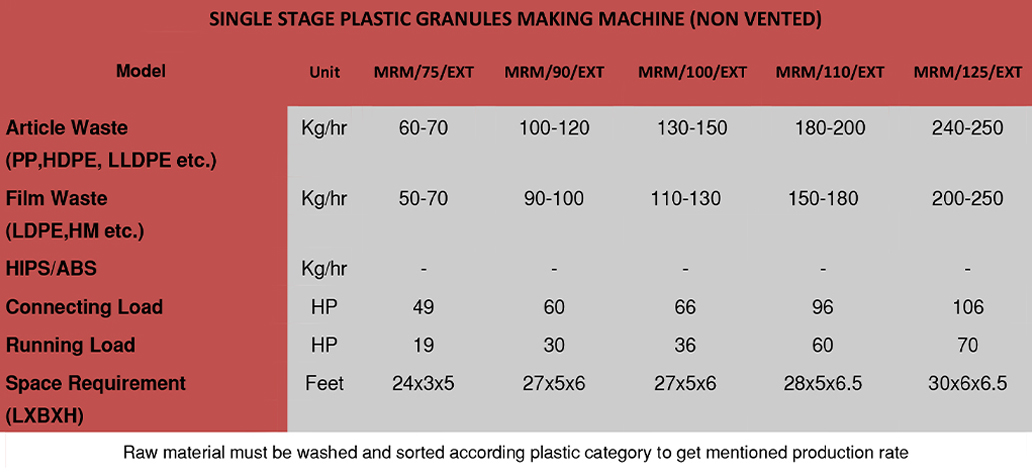

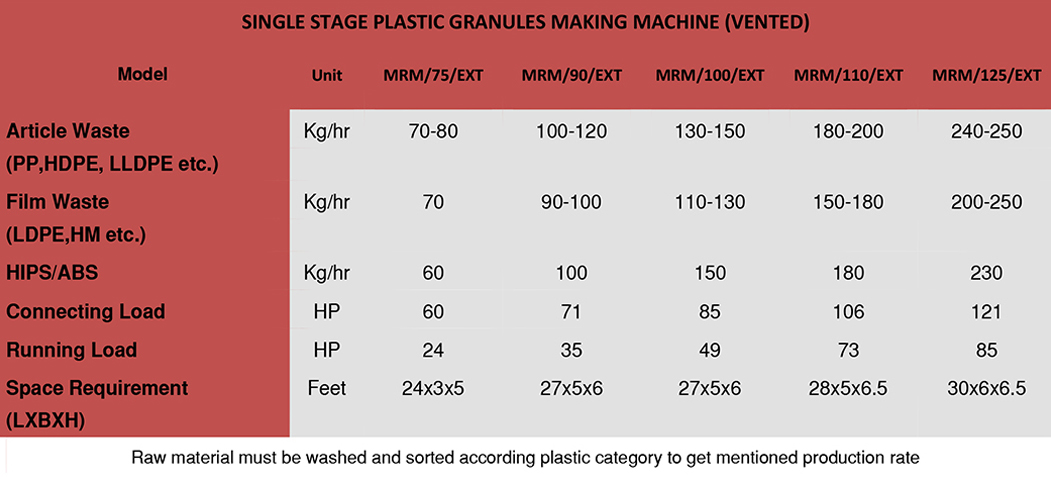

Range Of Models & Production Capacity :

Different types of models available, which are classified according production capacities,

- MRM/90/EXT : Production 100-120 kg per hour

- MRM/100/EXT : Production 150-200 kg per hour

- MRM/110/EXT : Production 200-250 kg per hour

Maximum Production Capacity 250 kg per hour in single stage plastic granules making machine. (production more than 250 kg per hour also available in mother baby plastic recycling machine segment.)

Important Features:

- Screw/barrel made of EN41-B mild steel material, nitrided and honing finished for quality production and longer durable life span.

- Screw designed for reprocessing, recycling and coloring application of plastic materials like LLDPE, HDPE, LDPE, PP, HM, PVC, ABS & HIPS.

- Screws are specially designed for specific material to get better production quality.

- Heating zones are divided on Barrel for accurate temperature control.

- Digital pyrocontrol panel for faster heating and easy operating.

- Thermocouples wires provided for each heating zone to control temperature with help of digital temperature controllers.

- Movable motor attachment provided for extruder’s AC motor and pelletizer motor to adjust motors as per belts length.

- Extruder’s fabrication is consisting of heavy and sturdy mild steel channel frame and covered with CRC sheets.

- High efficient hopper magnet provided to detect and restrict the metallic particles from the polymer.

- Screw is rotated by suitable AC motor with suitable heavy duty helical gear box. AC motor and helical gear box are from reputed make brands.

- Hydraulic screen changer provided for filtration of molten plastic.

- Die fitted with hydraulic screen changer which shapes molten plastic into plastic threads after filtration. Hydraulic power pack provided for screen changer.

- Cooling tank is fabricated from stainless steel 304 grade material, which mounted on mild steel fabricated stand. Where guide rollers are provided to convey the threads further towards pelletizer machine.

- Pelletizer machine’s stand is fabricated from heavy duty angles, where peletizer unit is mounted which has consisting sets of carbide tips moving blades. peletizer machine is driven by AC motor.

Optional Attachments :

- Tungsten carbide coated screw and barrel, for high production machines to increase screw life span.

- AC drives to maintain motor speed at desired rpm as per raw material requirement.

- Pressure transducer along buzzer system for hydraulic screen changer to detect pressure on mesh. (Helps to notify the labor to change screen on right time)(safety feature)

- Accumulator power pack for hydraulic screen changer to increase hydraulic up/down speed.

- Automatic hopper loader / Vacuum loader to load raw material into hopper with help of blower/vacuum. (substitutes labor)

- Air knife, to prevent water entering into pelletizer blade unit and remove water from pellets surface.

- Forced feeder, to feed low density raw material easily to increase production rate.

- Manual die head, instead of hydraulic screen changer. (to reduce the cost of machine) (best option for virgin material reprocessing)

- Barrel vent, for engineering grade materials like ABS and HIPS for moisture free pellets and quality output.

- PLC based HMI control panel with touch screen display (Advanced)

- Vibro shifter, to separate rejections and finished granules effortlessly.

Layout :

Process for Plastic Granules Making Machine:

.jpg)