Definition of Rotomoulding Machine

Rotomoulding is a plastics moulding engineering which is procedure for making each kind of hollow articles plastic products.

How It Works :

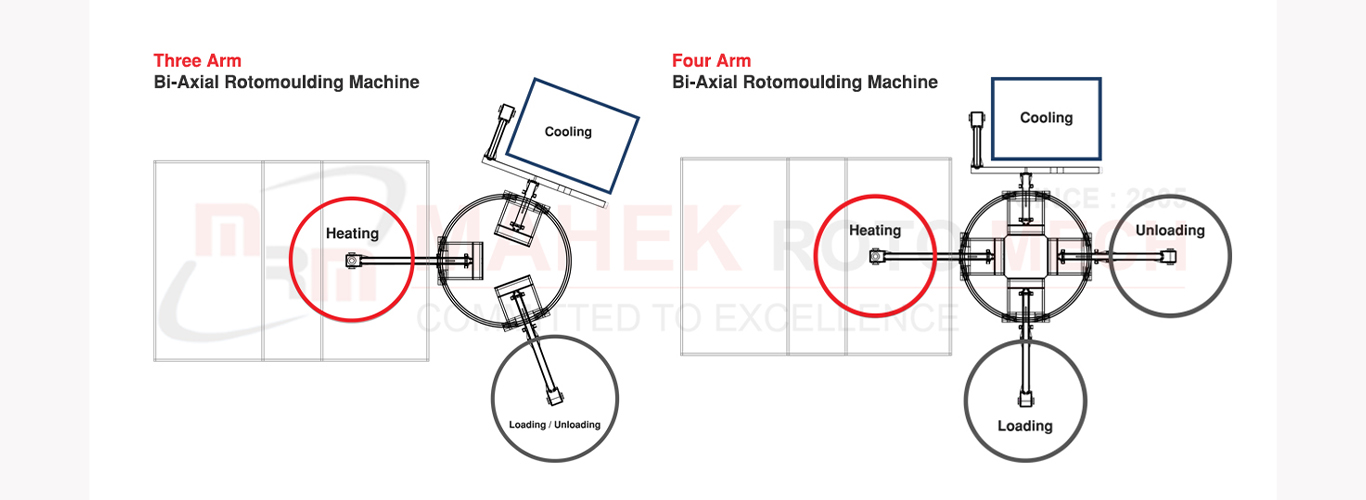

In the process, A Plastic Material (lldpe powder) is in powder state is inserted into a mould, which are fabricated from mild steel or stainless steel. Then the mould is closed and starts rotating on arms of machine. After that the mould starts getting heated in an oven and continues rotating and due to the heat, the powder gradually melts and ‘lays-up’ on the inside of the mould. Once the powder is completely melted, the mould is migrated to a cooling spot which has cooling fans and sometimes other processes used to cool down the temperature of mould. once the mould gets cool, the plastic powder comes into solid state. When the material gets completely cooled, the next step is to release that away from the mould surface. finally arm moves to the unloading spot and the product is taken out of the mould and then again cycle repeats.

Meanwhile in 4 arm Bi Axial Rotational Moulding Machine, cycle is constant. we explained it graphically in the layout.

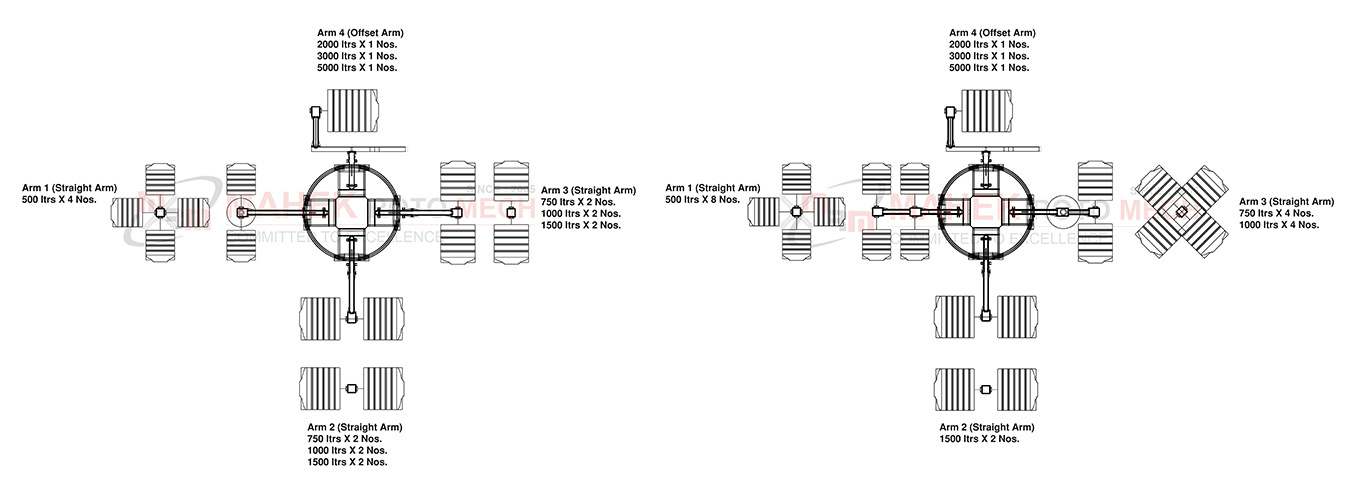

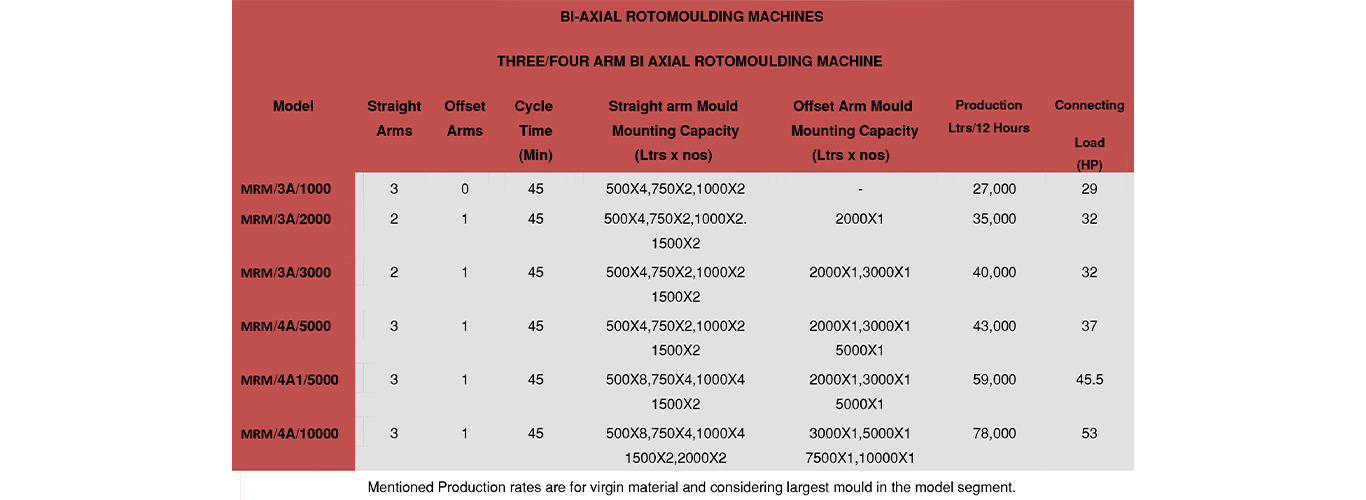

Range Of Models & Production Capacity :

Different types of models available, which are classified according production capacities and mould mounting capacity,

Four Arm Bi Axial Rotomoulding Machines : MRM/4A/5000, MRM/4A1/5000, MRM/4A/10,000 Three Arm Bi Axial Rotomoulding Machines : MRM/3A/1000-2000-3000-5000 etc.

Maximum Production Capacity Upto 10,000 ltrs in a single time.

These machine models are customizable, where client can choose amount of arms (maximum 4) and mould mounting options (from 500 to 10,000 ltrs for bi axial rotomoulding machine) according their requirements.

Important Features of Rotational Moulding Machine:

- Most efficient in fuel and energy consumption factor.

- Due to uniform heating of the mould with forced air circulation and smooth arm rotation, it is able to produce quality finish product.

- Highest production rate (due to lowestcycle time)

- Perfect distribution of raw material hence it is possible to produce article products with lesser weight.

- Most economical in the market due to lowest production cost.

- Low rejection rate due to sound and proven technology.

- Energy efficient and auto system burner from Italian brand.

- Eligible to produce up to six layer tanks due perfect distribution of raw material.

- AC drives provided for all minor & major axis’s arms for accurate speed and rpm control.

- Powder coated electrical control panel with dust proof construction & with all switch gears.

- Control panel contains, AC drives, digital indicators, temperature controller, timer and advance automation circuit for entire process control and all mandatory safety features.

Layout :

Popular Model: