Rotational Moulding Machine Manufacturer

Are you looking for a reliable and efficient Rotational Moulding Machine for your plastic manufacturing needs? We specialize in the design, production, and supply of advanced Rotomoulding Machines that offer consistent performance, energy efficiency, and cost-effective production.

How It Works :

Rotational Moulding, also known as rotomoulding, is a manufacturing process used to create hollow plastic products with uniform wall thickness. It’s a cost-effective and efficient method ideal for producing large, durable items such as water tanks, containers, toys, and industrial parts.

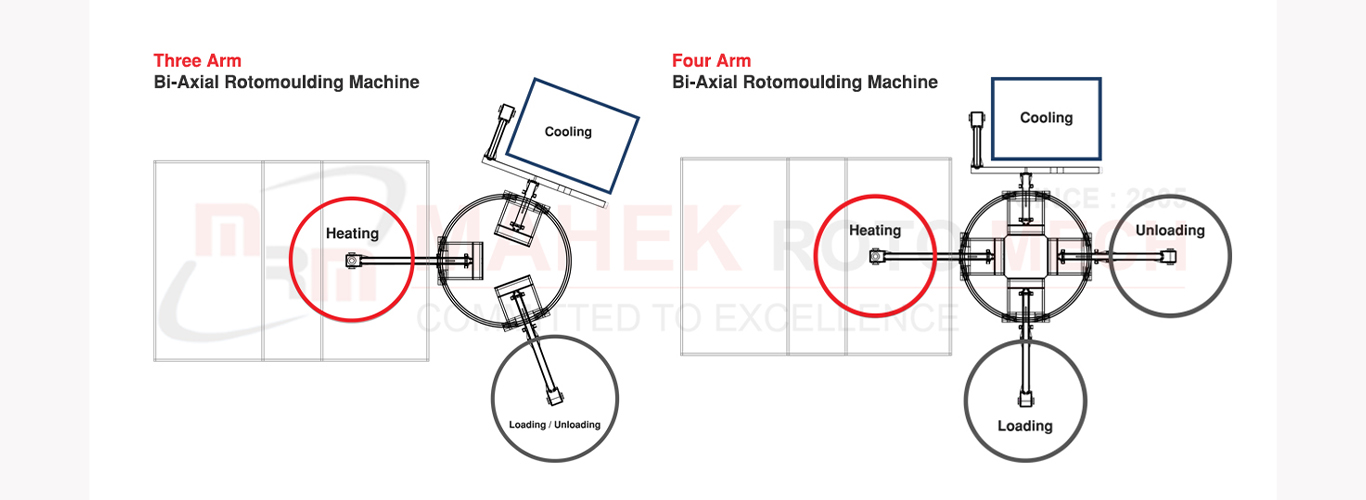

- 1. Loading the Mold

The process begins by loading a powdered or liquid plastic resin (usually polyethylene) into a hollow metal mold. The mold is then securely closed. - 2. Heating & Rotation

The mold is placed inside an oven, where it is heated while rotating on two axes (bi-axial rotation). This even rotation ensures the plastic coats the inside of the mold evenly, forming a consistent wall thickness. - 3. Cooling

Once the material is fully melted and formed, the mold is moved to a cooling chamber. It is cooled using air or water mist while continuing to rotate. This solidifies the plastic into the final shape. - 4. Unloading

After the plastic has cooled and hardened, the mold is opened, and the finished product is removed. The mold is then cleaned and prepared for the next cycle.

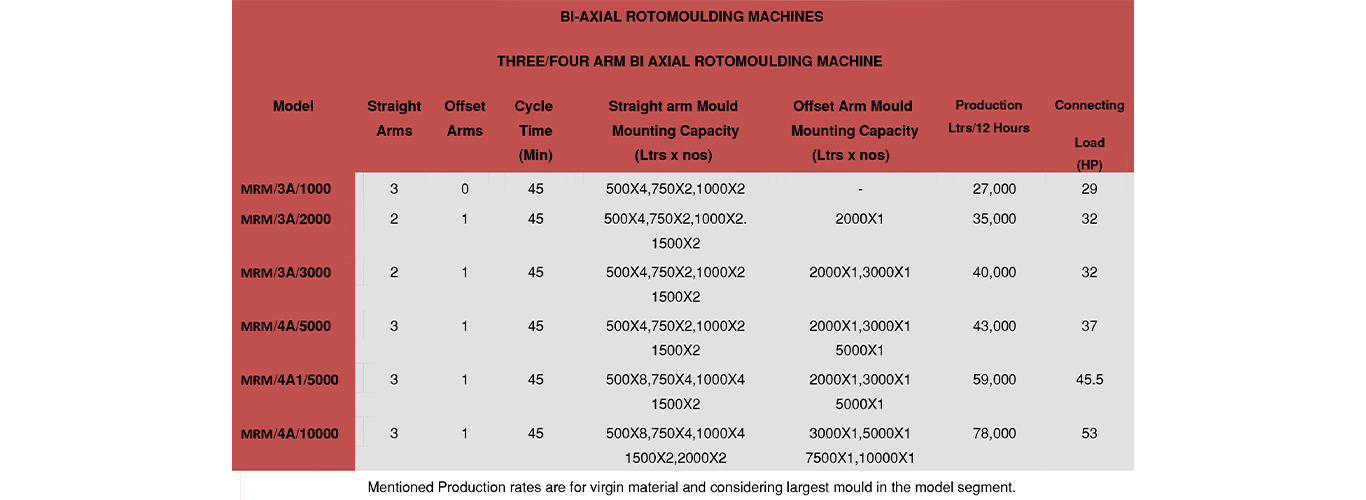

Range Of Models & Production Capacity :

| Machine Type | Product Size Range | Output Capacity |

|---|---|---|

| Bi-Axial Machine | 250L – 20,000L | Up to 8 tanks/cycle |

| Shuttle Type Machine | 250L – 10,000L | Up to 4 tanks/cycle |

| Rock and Roll Machine | Up to 7 meters in length | 1–2 large items/cycle |

| Lab/Prototype Machine | 1L – 100L | Low-volume sample production |

Important Features of Rotational Moulding Machine:

- Heavy-duty steel frame and arms

- Uniform heating and thickness

- Smooth surface finish and strong product integrity

- High-performance burners or electric heaters

- Reduced fuel or power consumption per cycle

- Programmable logic controller (PLC) based systems

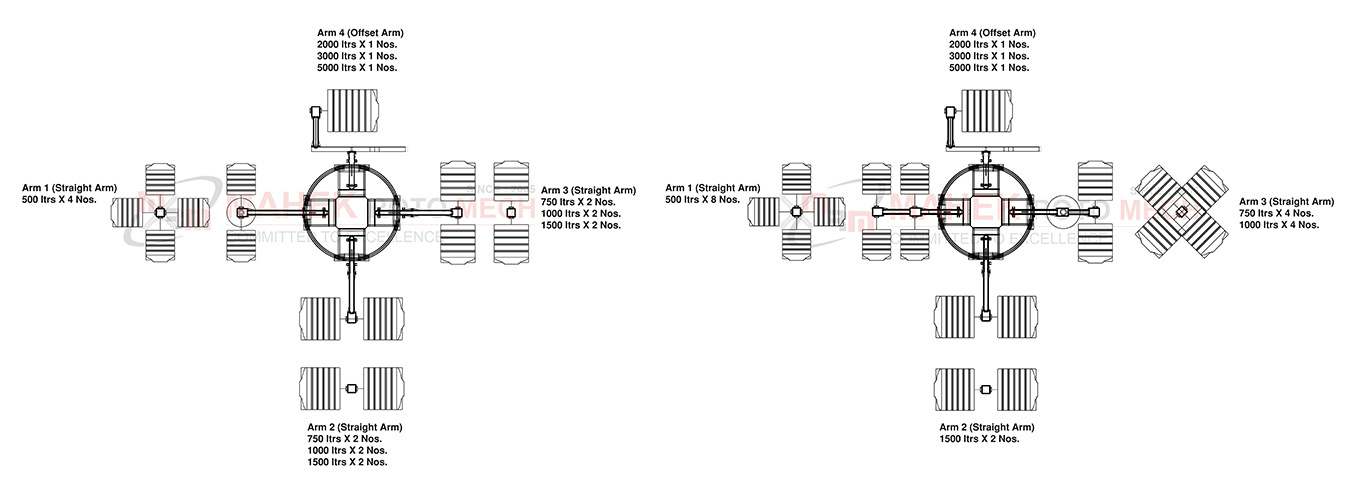

- Available in single, two, three, or four-arm setups

- Flexible production with simultaneous cycles

- Digital touch screen or push-button controls

Layout :

Popular Model: